Common challenges when building a passive house and how to overcome them

Interest in passive houses in Australia is growing steadily as more people seek homes that are comfortable, healthy, and energy-efficient. While the benefits are clear – lower energy bills, better air quality and year-round comfort – the process of designing a passive house can present challenges. Knowing what these are and how to manage them can make a big difference to the success of your build.

Understanding the standards

A passive design house adheres to strict performance standards that prioritise insulation, airtightness, thermal bridging, ventilation and solar gains. One of the first challenges is understanding the technical requirements and how they apply to your specific location in Australia. As with the original Passivhaus designed for a European context, climate conditions vary across Australia, so what works in Hobart may not suit Brisbane.

How to overcome it

Work with an experienced passive house designer or passive house builder who understands the certification process and climate-specific strategies. They can adapt passive house designs to your site and ensure the performance goals are realistic from the start.

Finding the right professionals

Not all builders have experience with passive home building. The construction techniques for airtightness, high-performance windows and continuous insulation are different from standard builds. Choosing the wrong team can lead to costly mistakes or performance issues.

How to overcome it

Look for certified passive house builders in Australia who can demonstrate previous projects. Ask for references and, if possible, visit completed homes to see the results first-hand. Collaboration between the passive home builder, architect and trades is essential for getting the details right.

Getting certified

For many, achieving official certification is the final step in a passive home building project. Certification confirms that the home meets the exacting performance standards set by the Passive House Institute. However, the process can be daunting if you are unfamiliar with the requirements.

How to overcome it

Rather than leaving it as the final step, plan for certification from the very beginning of your passive building design. This includes engaging a certified Passive House consultant or designer to guide the project, keeping accurate records of materials and construction methods, and scheduling all required testing at the right stages. Certification not only provides peace of mind that the home performs as intended but can also add value when selling.

Balancing budget and performance

A common concern with passive building design is that the initial costs may be higher than for conventional construction. High-performance windows, ventilation systems and insulation can add to the budget. Without careful planning, costs can rise quickly.

How to overcome it

Set a clear budget early and prioritise elements that have the biggest impact on energy performance. Good passive house designs in Australia often use value engineering – adjusting materials and specifications without reducing performance – to stay within budget. Remember that the long-term savings on energy bills and maintenance can offset the higher upfront investment.

Managing airtightness

One of the key features of a passive house design or certified passive home is airtightness. Achieving the required level can be challenging, especially if trades are not familiar with the methods. Poor airtightness can lead to heat loss, drafts and reduced comfort.

How to overcome it

Airtightness should be part of the plan from day one. Be sure all your tradies are clued up on sealing techniques, use quality membranes and tapes, and schedule regular blower door tests during construction. This allows any leaks to be identified and fixed before finishes are applied.

Selecting windows and doors

Windows and doors are often the weakest point in the building envelope. In passive house design, they must be high-performance and installed to prevent thermal bridging. Importing products can lead to delays and increased costs, while local options may not meet certification standards.

How to overcome it

Work with suppliers early to confirm lead times, certifications and installation requirements. Local manufacturers may be able to produce windows suitable for passive house builders. But, remember that a skilled installer is just as important as the product itself for ensuring airtightness and thermal performance.

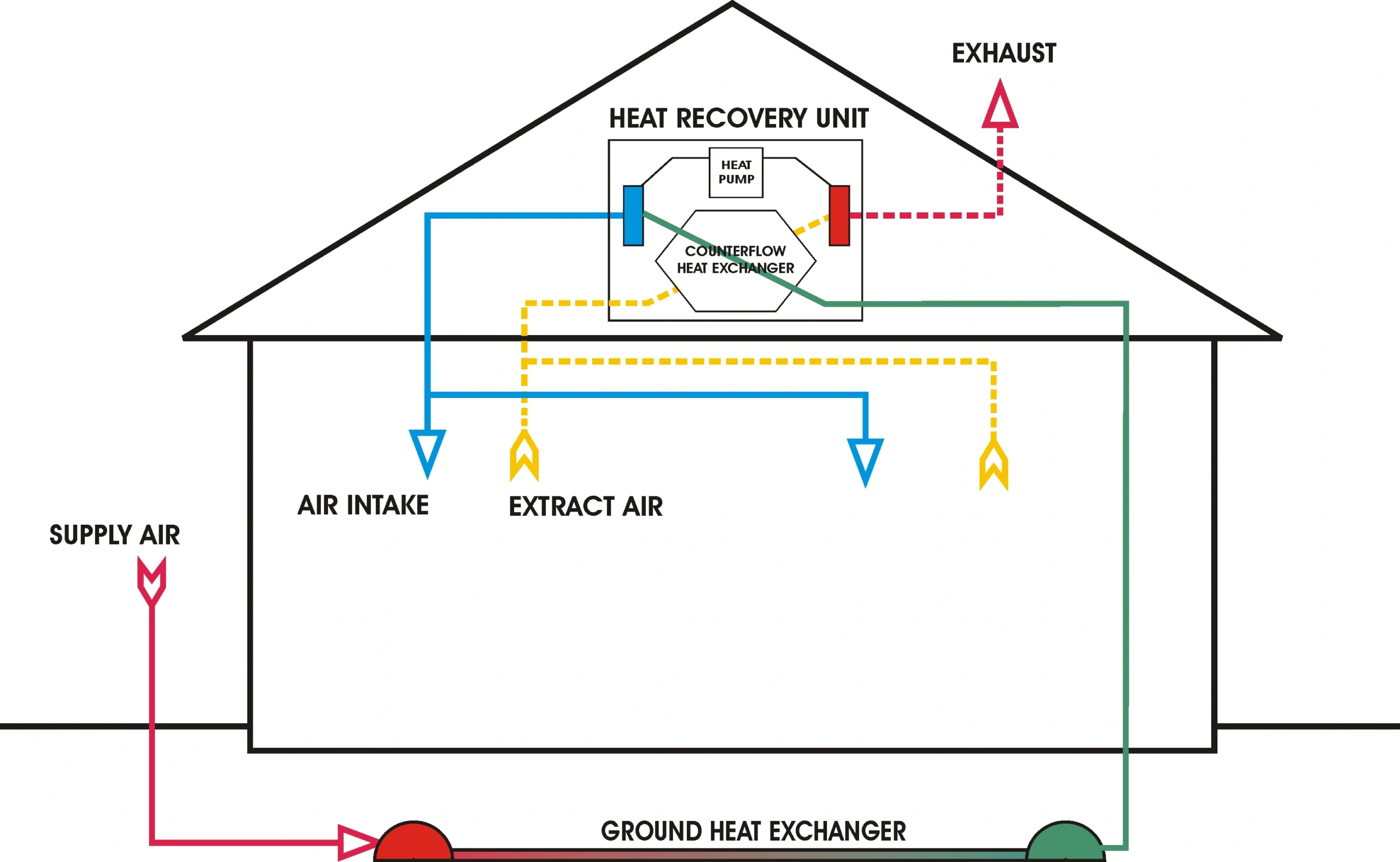

Integrating mechanical ventilation

A certified passive house builder will include a mechanical ventilation with heat recovery (MVHR) system to provide fresh, filtered air while recovering heat from outgoing air. This is not common in most Australian homes, so it can be unfamiliar to both homeowners and tradespeople.

How to overcome it

Engage a ventilation specialist during the passive building design phase. They can integrate ducting with minimal visual impact and ensure the system is balanced correctly. Educating the homeowner on how to operate and maintain the system is also essential for ongoing performance.

Managing solar gains

Solar passive house design uses the sun’s energy for heating and daylighting. However, in many parts of Australia, overheating can be a risk if the design does not account for seasonal variations and shading.

How to overcome it

Use detailed modelling to determine optimal window placement, shading devices and glazing types for your site. Adjustable shading, such as external blinds or pergolas with deciduous plants, can help control heat gain in summer while allowing sun in during winter.

Coordinating trades

As with most construction projects, building a passive design house requires all trades to work to a higher standard of detail and coordination. Gaps in communication can lead to performance issues, such as insulation gaps or unsealed penetrations.

How to overcome it

Have regular site meetings with the builder, architect and key trades to review details and progress. Encourage a culture of quality and understanding of why each step matters. When everyone is on board, the end result is far more likely to meet performance goals.